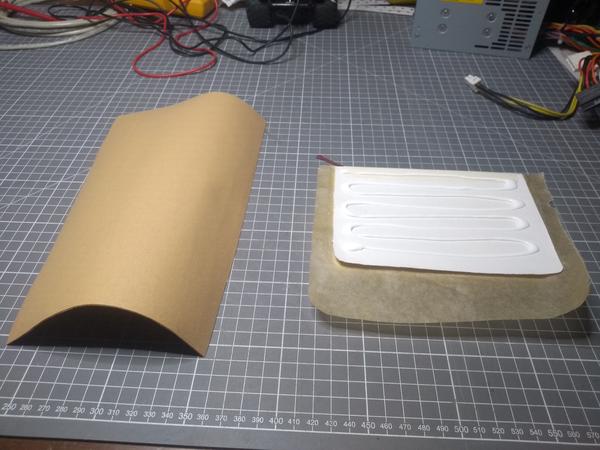

I had another few minutes to work on notebook #6 today. The cover is glued to the front side now. Next up, figuring out how to attach the rubber band that keeps the notebook closed, then glue on the rest of the cover.

Updates

(subscribe to news feed)I have a daily habit of working on side projects, and I've come to appreciate the benefits of tracking that habit out in the open. If I'm doing work on a software project, I track that on GitHub. If it's more hands-on, I like to post an update here.

-

-

I ostensibly finished my Prusa Mini enclosure a while ago, but alas, the double-sided tape I used to hold the power setup on the back didn't hold. The power supply was too heavy, and when it fell, it pulled everything else with it. So I've printed this holder for it.

Very happy with how it came out! Seems very sturdy. I expect it to hold this time.

-

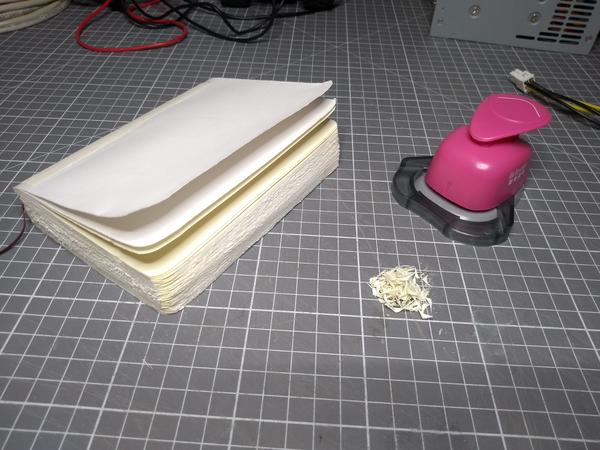

Rounded the corners of notebook #6 today. That means the text block is finally finished! Up next (hopefully next weekend), putting on the cover.

-

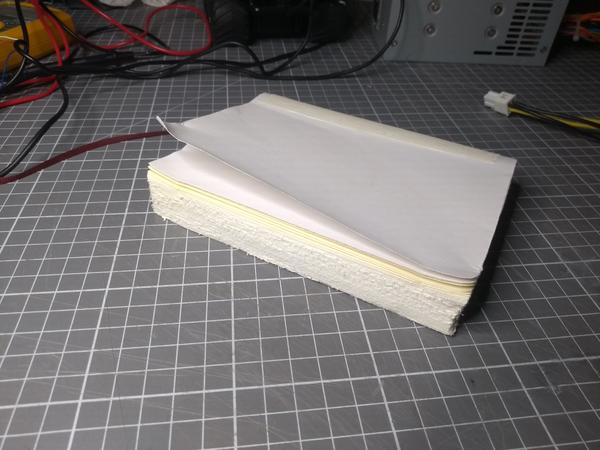

Finally finished sanding notebook #6! This one took the most sanding out of all of them. Now it needs to go into the book press for a bit, then I'll round the corners. After that, it's finally time for the cover.

-

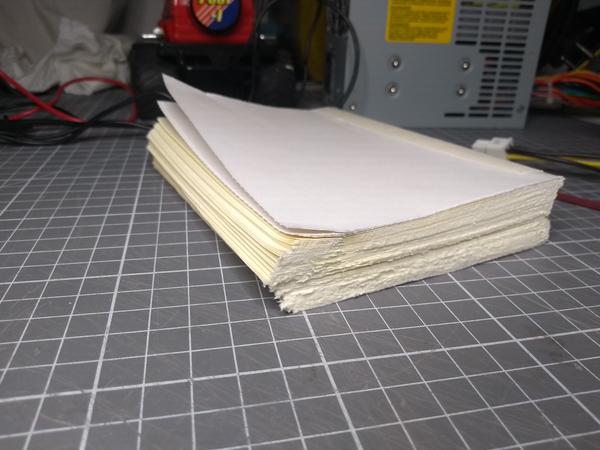

Finished another side of notebook #6 today. More sanding to do on the last side, hopefully next weekend.